JOIN OUR TEAM

Build a Career at Mid-America Machining

Mid-America Machining is a financially sound, privately held company that has been in business for over 35 years with no layoffs. We show our appreciation to our hard-working team by providing the following:

- Competitive wages

- In-house training by our highly experienced team

- Climate-controlled year round

- Clean, bright work environment

- State of the art equipment

- Comprehensive benefit package:

- Employees pay $ZERO$ for health insurance premiums & coverage starts immediately!

- Health Savings Accounts (company contributes $750/$1500 annually)

- Dental & Vision insurance

- Short-Term & Long-Term Disability

- Life Insurance

- Vacation, paid holidays & Christmas bonuses

- 401(k) with employer contributions

Click the Contact Us button below to send an email to the Human Resources Director, Jenna Berry.

CAREERS

How to Apply

Email resumes and/or applications to:

employment@mid-americamachining.com

Pickup/drop-off applications at 11530 Brooklyn Rd, Brooklyn, MI (Boxes outside for after hours). We are always reviewing applications/resumes looking for dedicated, honest and hard-working people to join our team!

Employment Opportunities

BLANK

Experienced & Trainee Positions Available

Job Description:

Are you an experienced Mold Maker/Machinist who is currently employed? We encourage you to apply! We’d love to discuss whether Mid-America Machining has more to offer in regards to benefits, compensation & overall work environment. New to Mold Making? Are you looking for a hands-on job where you can see direct results from your hard work? We are looking for up to 5 Mold Makers. Individuals looking to train with the best are encouraged to apply. The Mold Maker Trainee job is an entry-level position that consists mainly of disassembling, cleaning and assembling extrusion blow molds. Our Mold Maker Trainees will be trained by highly experienced Mold Makers. They will eventually be trained to use mills, sand blasters, drill presses and metal finishing tools. Applicants must have some familiarity with basic hand tools such as allen wrenches, hammers and screwdrivers. Thoroughness and attention to detail are important aspects of the job. During assembly of the mold, it is important to make sure the molds are clean, deburred and that all bolts are tightened properly. There is potential for growth depending on individual capabilities & company needs. We are looking for someone with a great work ethic, a dependable attendance record, a positive attitude, who is mechanically inclined and has some understanding of math. Must be able to work 45+ hours a week (M-F & some Saturday mornings). Must be able to lift up to 50 pounds. Looking to hire on for 1st, 2nd & 3rd shift; however, willingness to work 2nd or 3rd shift in the future is a plus. Training for 2nd and 3rd shift takes place on 1st shift.

Job Description:

- Daily tasks include direct communication with our sales team, customers, and manufacturing department to develop new bottle designs and/or enhance our current products.

- Throughout this process our Product Design Engineers compile package requirements such as: volume, fill level, overflow, overall size, height, width, depth, bottle gram weight, neck finish type and label stipulations.

- In addition, any performance requirements, such as top load and drop test, will need to be identified and qualified by the customer. Bottle testing and measurements of sample containers will be conducted in our bottle lab to include: measuring overall bottle and neck finish dimensions, calculating volume, fill level, and overflow, and checking container weight, wall thickness and material distribution. These measurements will be taken using instruments such as an optical comparator, digital height gauge, calipers, and Magna Mike.

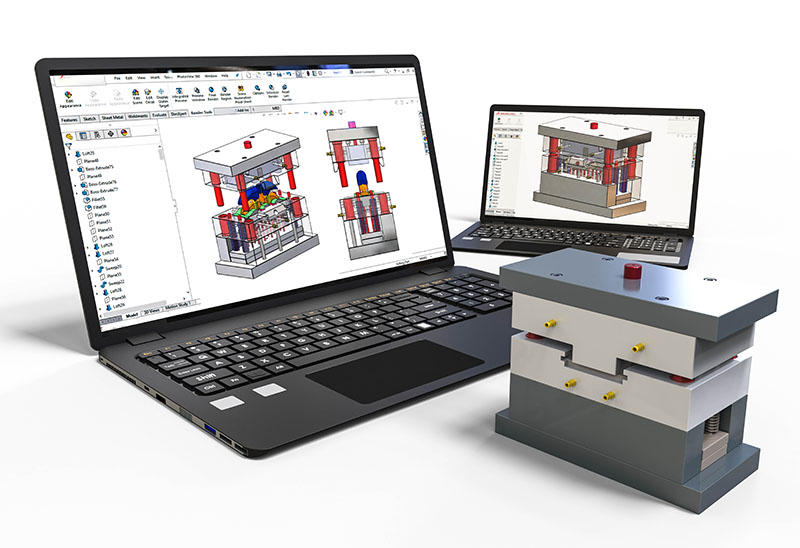

- SolidWorks 2024 is used to develop fully parametric 2D sketches. The solids and surfaces will be driven from these 2D sketches to develop new product bottle designs. 3D computer models will be generated, and in many cases 3D models will be produced on our in-house 3D printer. Once approved, a scaled cavity is created applying the required shrink rate to yield target container dimensions, from which finished molds will be produced.

- We also have a Faro Arm laser scanner with Polyworks software used for reverse engineering.

Qualifications:

- 5+ years working experience in related field.

- Minimum of bachelor’s in engineering or 7 years’ experience in related field.

- Preferred degrees: Mechanical Engineering, Mechanical Engineering Technology, Product Design Engineering Technology or Packaging Engineering

- 5+ years CAD experience (SolidWorks preferred and/or NX).

- Proficient in SolidWorks.

- Equivalent combinations of education and/or experience will be considered.

- Strong mechanical ability and knowledge of extrusion blow mold equipment.

- Excellent Communication

- Proficient in the use of Microsoft Office suite applications

- Experience with a Faro Arm Laser scanner & Polyworks is a plus.

Job Description:

- Daily tasks will include direct communication with our Sales Team, Customers and Manufacturing.

- Working together with Product Design you will use SolidWorks 2024 to develop fully parametric 2D sketches.

- The solids will be driven from these 2D sketches to develop 3D mold designs. Within these 3D designs we develop the cooling line / channels that best suit the container shape to provide the customer with optimized cooling for enhanced cycle time.

- You will also be required to design venting, scrap chambers, neck finish and adapt the mold to the customer blow mold machine platform.

- In some cases, we also design die tooling to provide optimal wall thickness in the end product. Within the design of the neck finish you will be required to research shrink rates (within company history) to apply these to an excel embedded design table which drives dimensions to yield in spec container neck finishes.

Qualifications:

- 5+ years working experience in related field.

- Minimum of bachelor’s in engineering or 7 years’ experience in related field.

- Preferred degrees: Mechanical Engineering or Mechanical Engineering Technology.

- 5+ years CAD experience (SolidWorks preferred and/or NX).

- Proficient in SolidWorks.

- Equivalent combinations of education and/or experience will be considered.

- Strong mechanical ability and knowledge of extrusion blow mold equipment.

- Excellent Communication

- Proficient in the use of Microsoft Office suite applications

2nd & 3rd Shift

Job Description:

Are you an experienced CNC Machinist who is currently employed? We encourage you to apply! We’d love to discuss whether Mid-America Machining has more to offer in regards to benefits, compensation & overall work environment (current employment is not required). The job involves set-up, loading and operating of CNC machinery such as Makinos, Okumas, Haas, Fadals, Sharnoas, (Vertical and Horizontal Machines/3 and 4 axis). New hires will initially work on first shift for an unspecified period of time to learn our processes. Requirements: Must adhere to blueprints, written & verbal instructions. Ability to use indicators and measuring equipment.

Qualifications:

H.S. Diploma or GED, one year of machining experience, ability to work overtime, some tools required (tool purchase program available). Must be able to lift up to 50 lbs.