MID-AMERICA SERVICES

Product Development & Engineering

At Mid-America, our success is built on a strong foundation of research and development, driving innovation, and problem-solving. We firmly believe that continuous improvement is key, and our commitment to R&D remains unwavering. Our process development area is equipped with cutting-edge facilities, allowing us to handle mold and prototype development seamlessly. Under the skilled guidance of our experienced process technicians, we conduct confidential development processes, ensuring your projects receive the utmost care and attention they deserve. At Mid-America, we are dedicated to pushing boundaries, and our R&D efforts exemplify our determination to stay at the forefront of innovation and deliver top-notch solutions for our valued clients.

ENGINEERING EXPERTS

Design Capabilities

At Mid-America Machining, we leverage cutting-edge software platforms to ensure our customers receive top-notch services and results. Our team is highly proficient in a variety of advanced software tools, including SolidWorks 3D software, Siemens NX software, Mastercam, Dellcam PowerMill Cam system, and Hyper Mill.

Modeling & Reverse Engineering

At Mid-America Machining, we offer unit cavities and prototypes to help you verify your needs before moving to the production mold stage. We also provide expedited prototyping services for quick testing and customer approval. Our reverse engineering process utilizes laser scanning technology to gather direct point cloud data, ensuring precise geometry capture. Our modeling capabilities include SLA models, MAM-direct CAD data models, and visual models. In addition, we use a Stratasys F270 for 3D printing full-scale bottle designs, allowing you to see a physical representation of your part before finalizing the mold design.

Modeling & Reverse Engineering

At Mid-America Machining, we offer unit cavities and prototypes to help you verify your needs before moving to the production mold stage. We also provide expedited prototyping services for quick testing and customer approval. Our reverse engineering process utilizes laser scanning technology to gather direct point cloud data, ensuring precise geometry capture. Our modeling capabilities include SLA models, MAM-direct CAD data models, and visual models. In addition, we use a Stratasys F270 for 3D printing full-scale bottle designs, allowing you to see a physical representation of your part before finalizing the mold design.

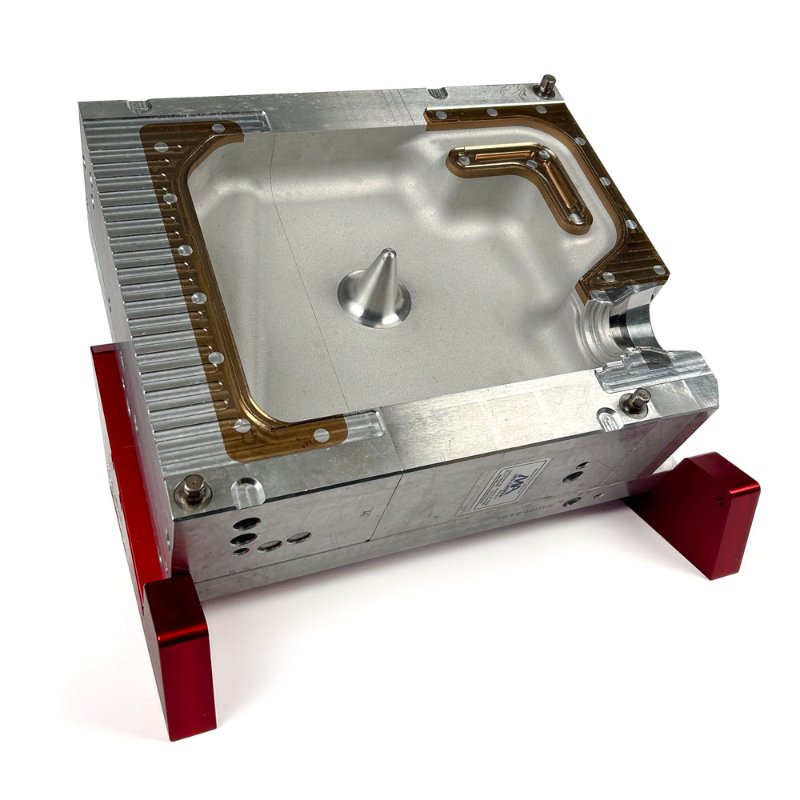

Mold Design & Development

In the mold design phase, we seamlessly integrate your container design with your designated machine platform to ensure optimal tooling performance. By carefully considering various design factors and utilizing select mold materials, we create molds that deliver exceptional performance. Our expert engineers utilize SolidWorks 3D modeling software, enabling us to maximize cooling efficiency and other crucial attributes while developing production-worthy molds. Technology certainly plays a role in enhancing efficiency and accuracy, but it's the wealth of experience of our engineering staff that truly sets us apart. With years of direct experience in blow molding, our team skillfully combines expertise and technology to bring your mold design to its highest potential.

HIGH END PERFORMANCE

Lab Testing Equipment

Mid-America prioritizes quality testing with cutting-edge equipment for accurate and reliable results. Our Mecmesin Top load testing machine allows us to address customer requirements and evaluate bottle performance effectively. For durability assessment, we use the Lansmont PDT-80M precision drop testing machine, accommodating tests up to 71 inches in height and 150 lbs package weight. Additionally, our bottle development and evaluations benefit from the Olympus 8500 Magna-Mike, ensuring consistent quality and performance. Trust Mid-America to deliver innovative and durable products that surpass expectations, thanks to our commitment to advanced testing methodologies.

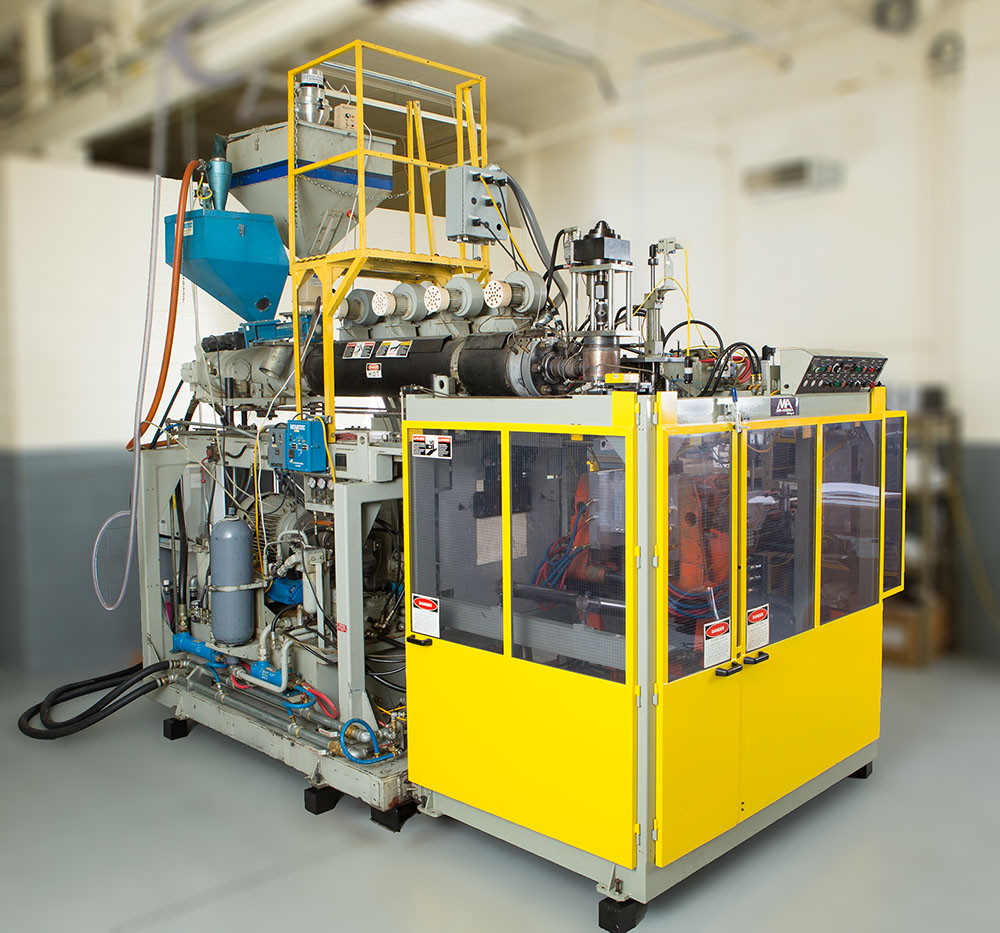

Lab Machines

Mid-America Machining provides comprehensive blow mold sampling services, allowing us to thoroughly assess all container performance characteristics during the development phase. From conceptualization to the final finished container, we offer complete container development services. Our sample testing machines, including reciprocating screw and shuttle applications, further enable us to ensure the highest quality and functionality of the containers we produce. With a focus on excellence and attention to detail, we are committed to delivering exceptional solutions tailored to meet your specific needs.

Reciprocating Screw 250R1

A 2.5″ reciprocating screw extruder equipped with a single parison head, programming side shift, and other advanced features. With this equipment, we offer sampling capabilities ranging from 4 oz. to 2 gallons, allowing for unit cavity sampling, market testing, performance testing, and line trials.

Shuttle Comec MSC/S Series

A high-performance continuous extrusion single parison head single-sided machine. With sampling capabilities ranging from 4 oz. to 2 gallons, this cutting-edge equipment allows us to conduct unit cavity samples, market testing, performance testing, and line trials.