ABOUT MID-AMERICA MACHINING

Traditional Skills with a Modern Approach

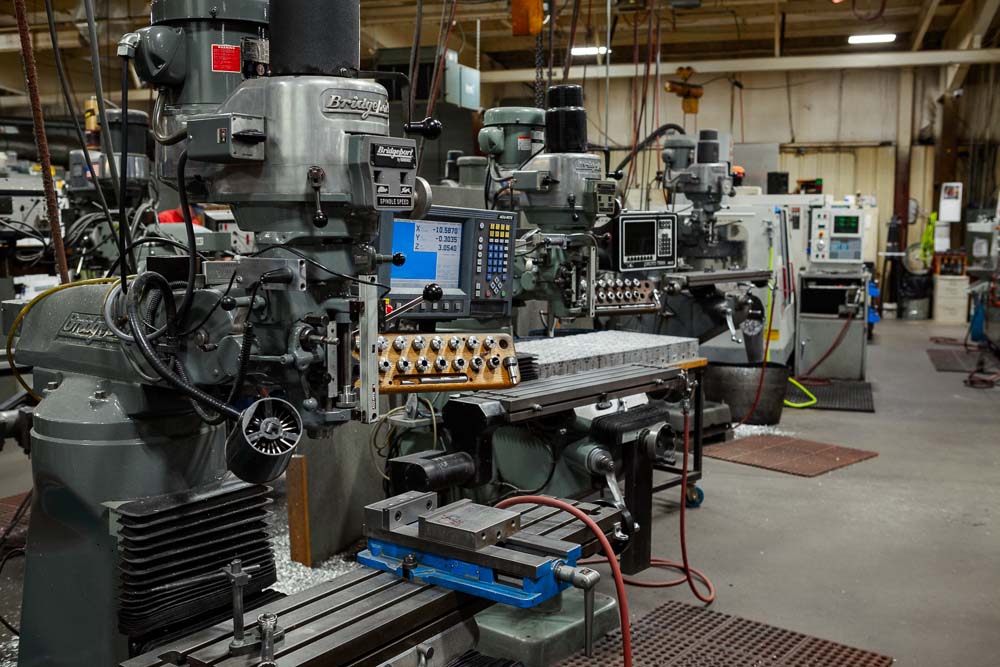

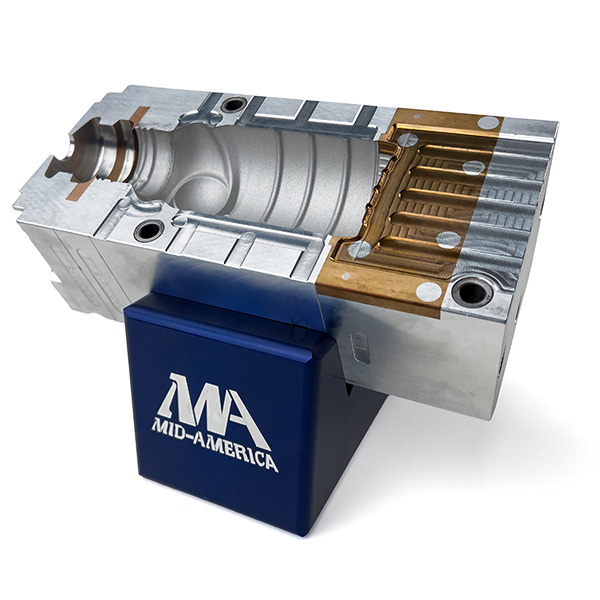

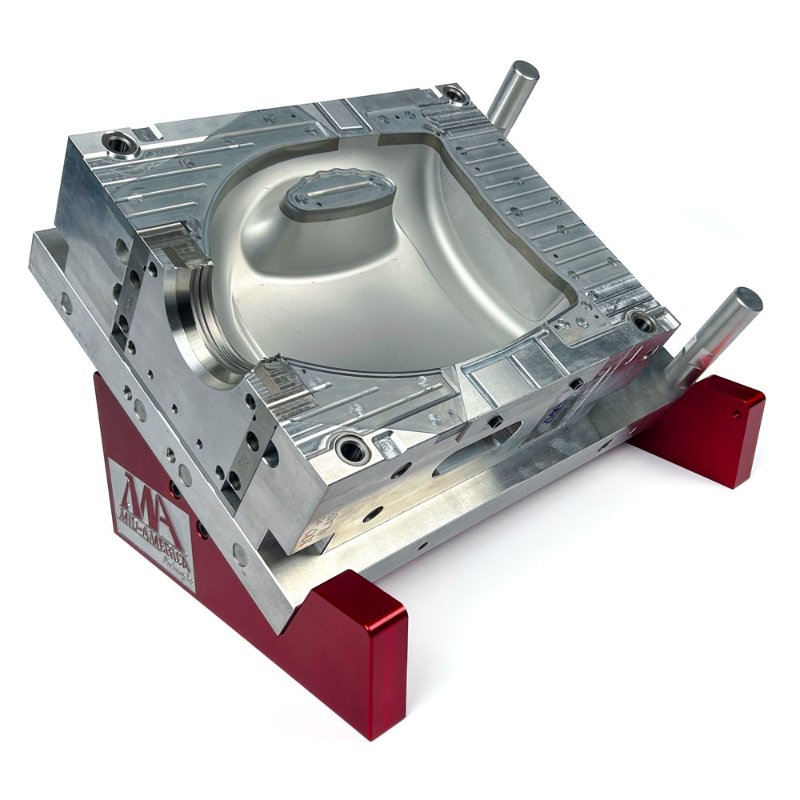

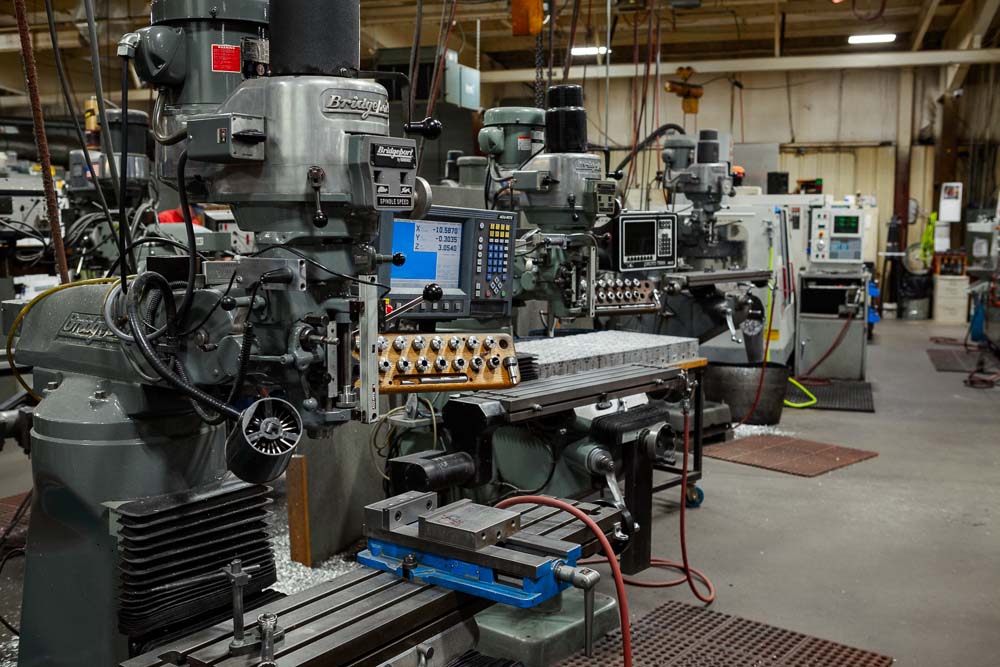

At Mid-America Machining, we combine a wealth of traditional machining knowledge with advanced equipment and processes to deliver precise results time and time again. What sets us apart from other mold makers is our extensive firsthand experience that goes beyond the blow mold itself. Our team's experience allows to fully understand a wide range of machinery platforms and applications.

ABOUT MID-AMERICA MACHINING

Traditional Skills with a Modern Approach

At Mid-America Machining, we combine a wealth of traditional machining knowledge with advanced equipment and processes to deliver precise results time and time again. What sets us apart from other mold makers is our extensive firsthand experience that goes beyond the blow mold itself. Our team's experience allows to fully understand a wide range of machinery platforms and applications.

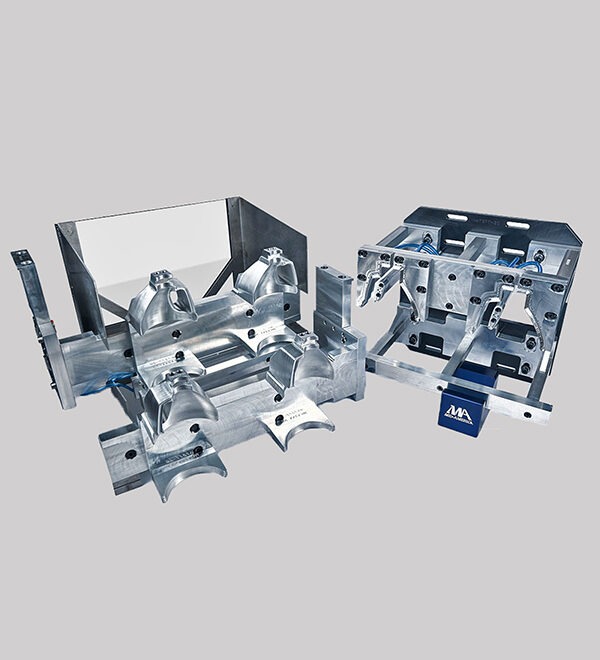

EXTENSIVE CAPABILITIES

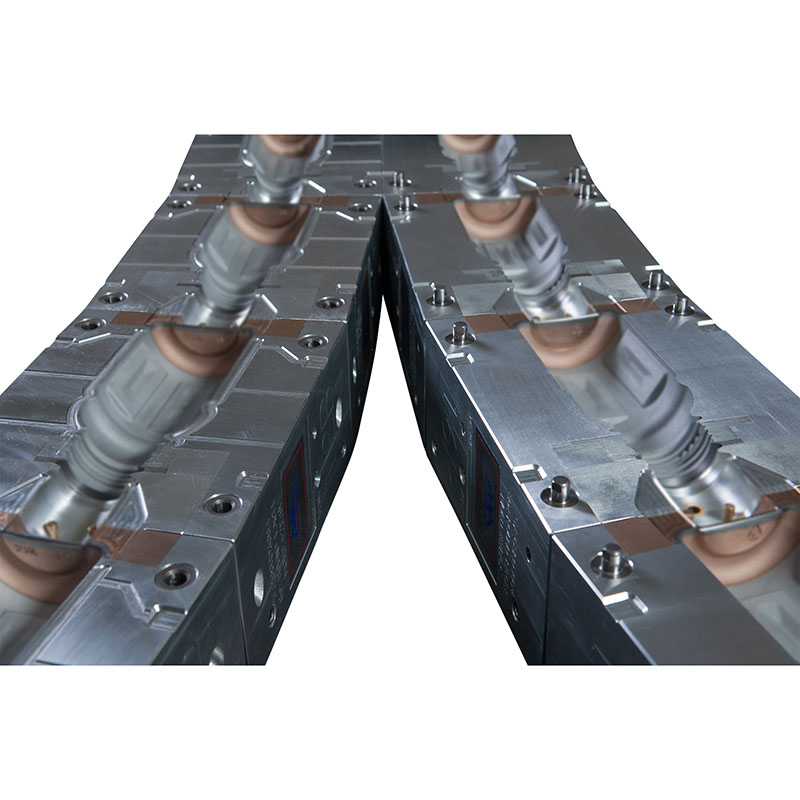

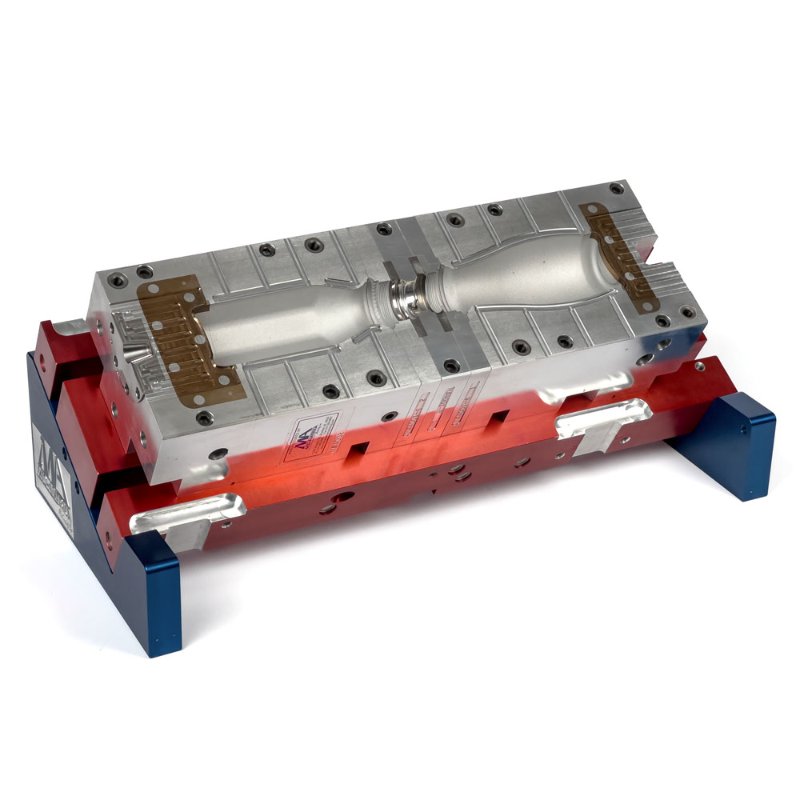

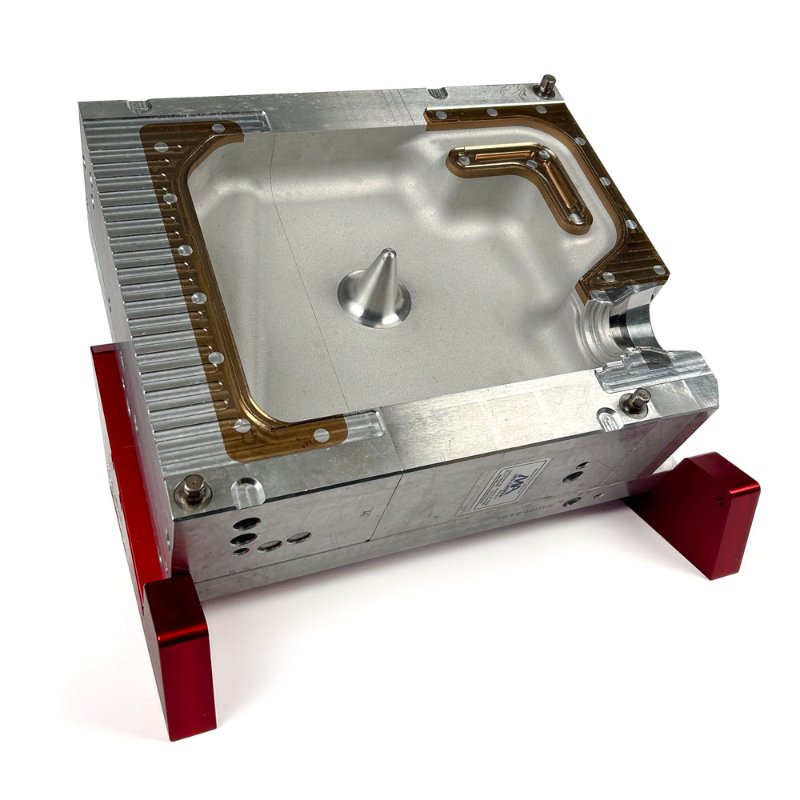

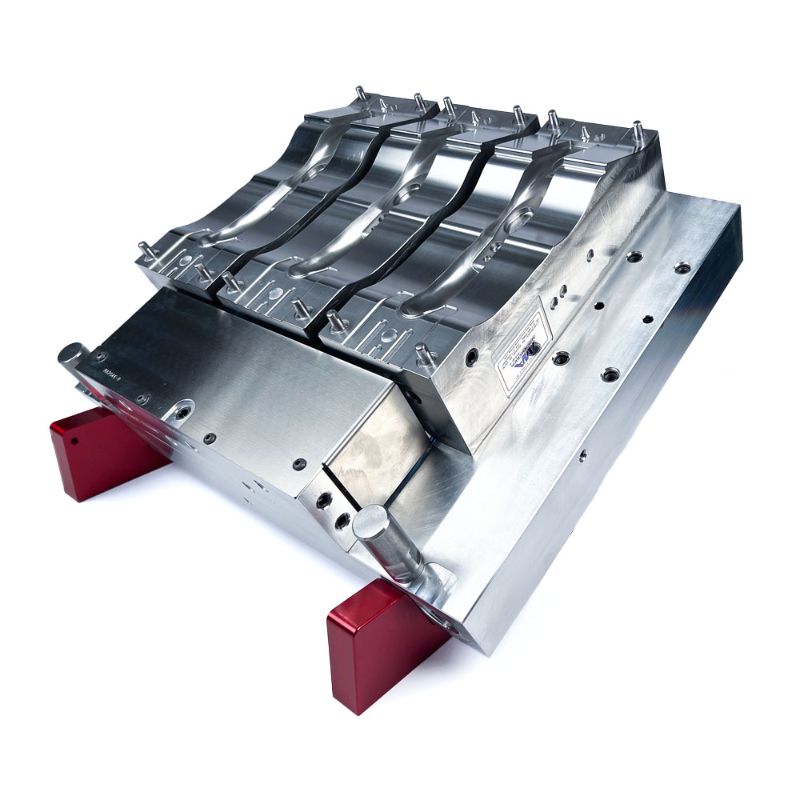

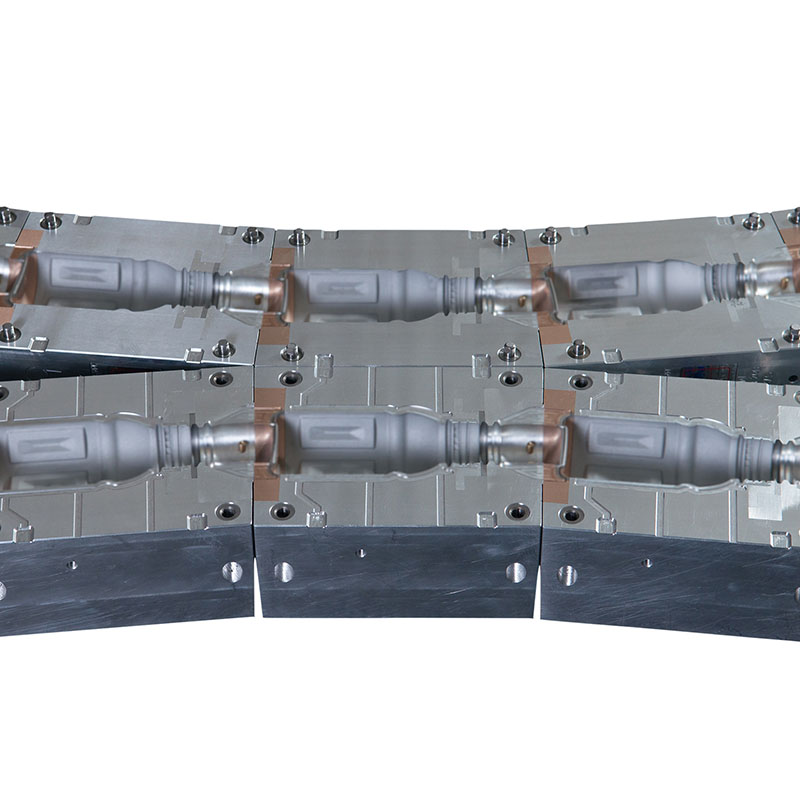

Extrusion Blow Mold Services

- Research & Development

- Modeling

- Design Capabilities

- Reverse Engineering

- Trial Machine

- Qualifications

- Mold Making

- Inspection

- Mold Repair & Reconditioning

- Trim & Head Tooling

- Blow Pin Assemblies

EXTENSIVE CAPABILITIES

Extrusion Blow Mold Services

- Research & Development

- Modeling

- Design Capabilities

- Reverse Engineering

- Trial Machine

- Qualifications

- Mold Making

- Inspection

- Mold Repair & Reconditioning

- Trim & Head Tooling

- Blow Pin Assemblies

COMPANY TIMELINE

OUR HISTORY

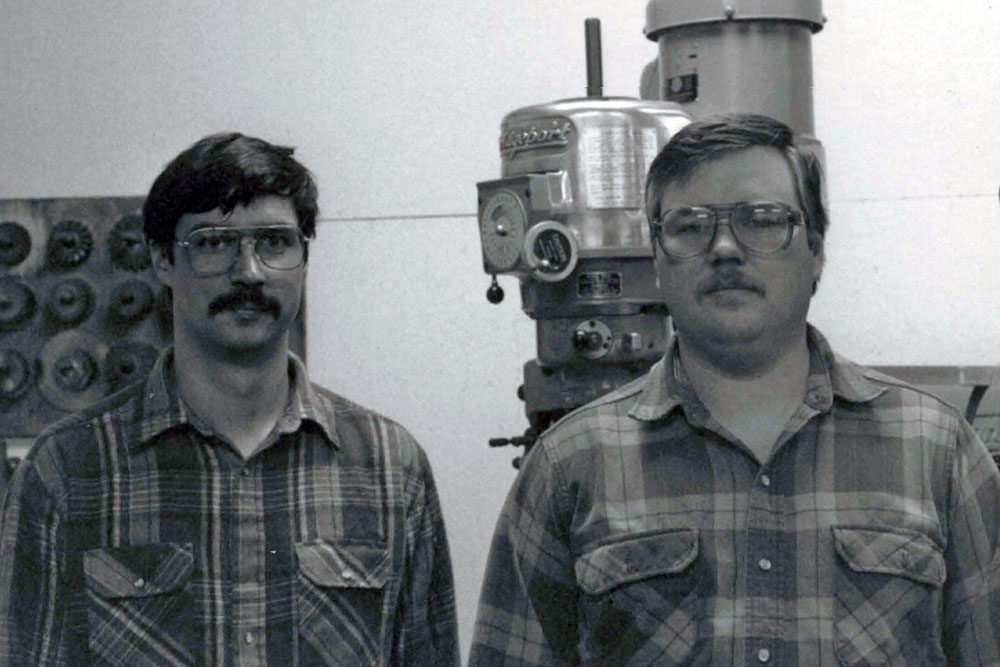

Mid-America Machining was founded in 1988 by Mark Berry who began the company in his garage. The first shop was a 2500 square foot facility with just two employees in Norvell, MI.

In 1991, Mid-America Machining began producing blow molds, trim tooling and other related tooling for a major blow molding machinery manufacturer.

In 1998, the company expanded to 15 employees and acquired high-speed machining technology.

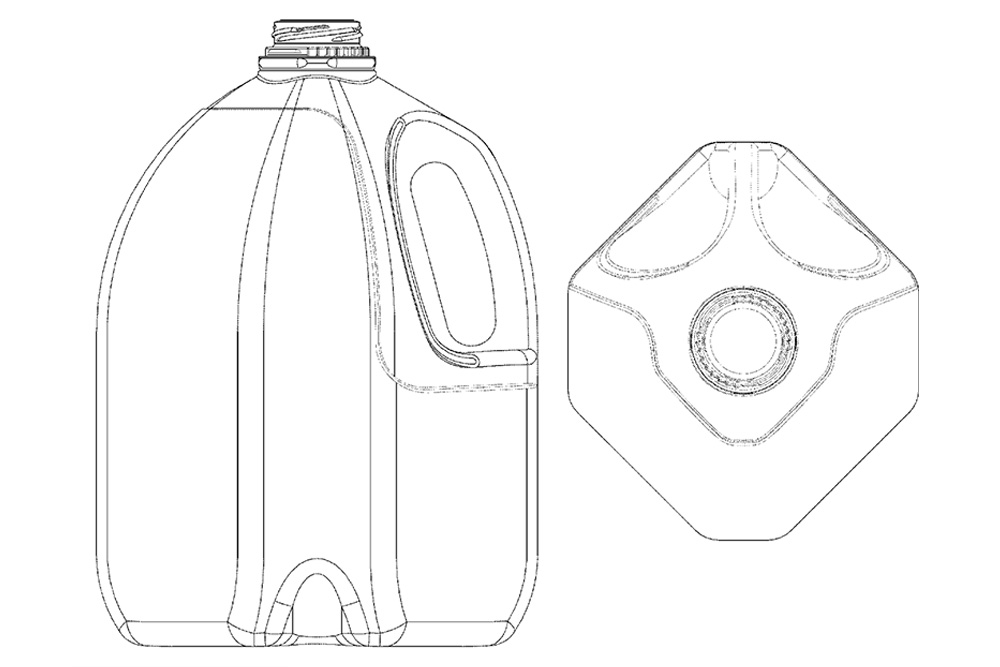

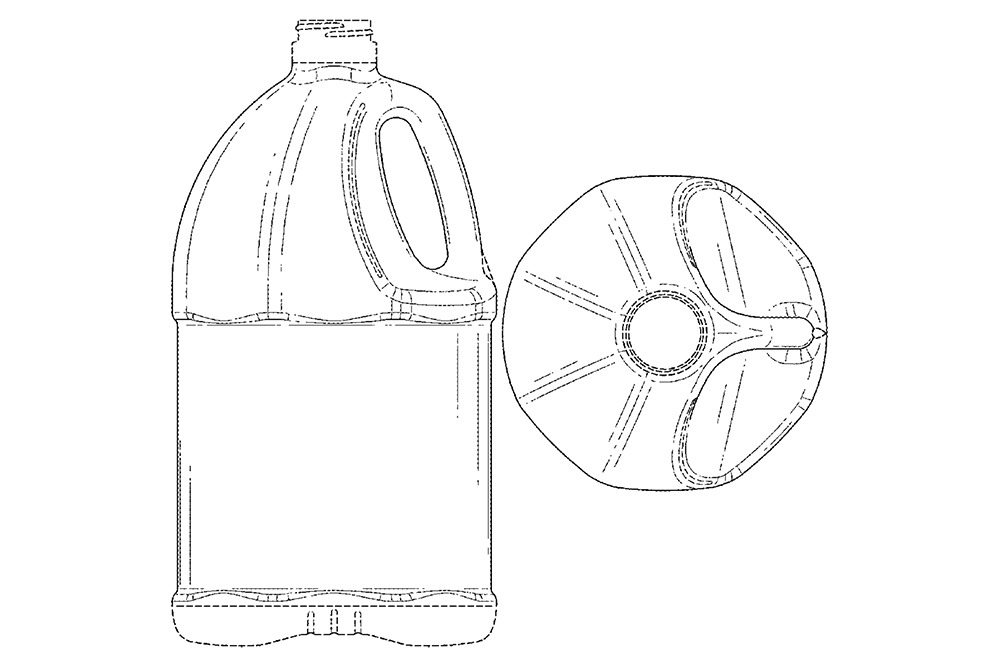

Mid-America was granted patents for the Family of Lightweight Dairy Designs.

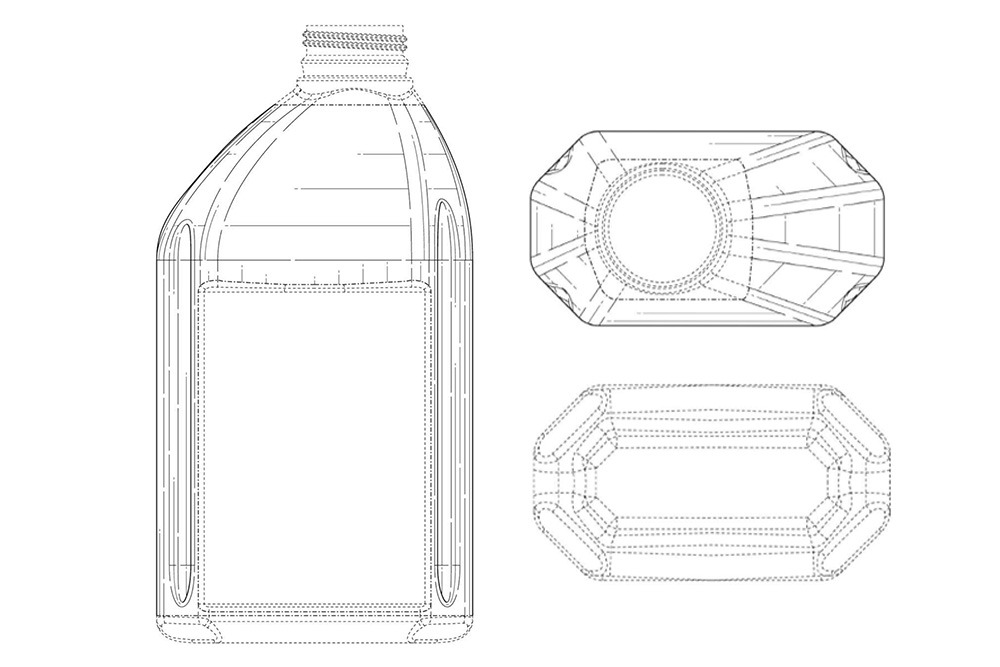

Mid-America was granted the lightweight Industrial Round patents.

Mid-America was granted the lightweight oil container patent.